Products

Rock Wool Sandwich Panel

Categories:

Rock Wool Sandwich Panel

E-mail: haijiecaigang@163.com

Phone/WhatsApp: +8615650357879

Description

The color steel rock wool sandwich panel and its production process realize the compounding of rock wool and steel plate into a whole through automated equipment in the factory, thus changing the previous method of on-site compounding of rock wool panels, and meeting the requirements of building thermal insulation. , On the premise of sound insulation, fire prevention and other requirements, it has achieved the goals of high quality, high efficiency, reliability and safety. This product has been widely used in Europe and has matured and perfected.

Rigid waterproof tongue and groove,preventing reverse osmosis of rainwater.

Special tongue and groove structure, ensuring the reliable wind-resistant performance of cladding under strong wind.

Concealed tapping screw,ensuring aesthetic property of wall surface and prevent head corrosion.

Polyurethane side-sealing technology,greatly enhancing the integrated bearing capacity of steel plate and ensuring the overall strength of tongue and groove.

With common-length build-in connection for plate edge, ensuring the firm connection.

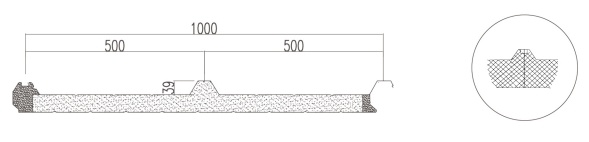

Schematic diagram of board type and lap joint

Product Advantage

Energy saving and heat preservation: superior heat preservation and insulation performance.

Flame retardant and fireproof: through the "National Quality Supervision Center for Fixed Fire Extinguishing Systems and Fire-Resistant Components Inspection", the combustion level reaches GB8624 B1 level standard.

Airtight sound insulation: sound insulation is good, the sound caused by the impact of rain, hail and other sound reduction effect.

Waterproof and rustproof: large span, fast drainage, good waterproof effect, hidden screws, not easy to rust, prolonging the service life of the plate.

Aesthetics and economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs.

Quick construction: heat preservation and decoration integration, easy to lap.

Product Parameters

| Effective coverage width | 1000mm | ||

| Color steel thickness | 0.4~0.7mm | ||

| Conventional color | White grey/scarlet red/sea blue/iron blue grey etc. (other colors are customized) | ||

| Recommended Coating | PVDF fluorocarbon coating/SMP silicon modified coating/HDP high weather resistant coating/PE common polycool coating | ||

| Core thickness | 50/60/75/80/100/150mm | ||

| Optional core material | Polyurethane vinegar | Rock wool with polyurethane sealing | Glass wool with polyurethane sealing |

| Thermal conductivity | ≤0.023w/m·k | ≤0.035~0.041w/m·k | ≤0.037~0.043w/m·k |

keyword:

Rock Wool Sandwich Panel